About Stripseal Expansion Joint

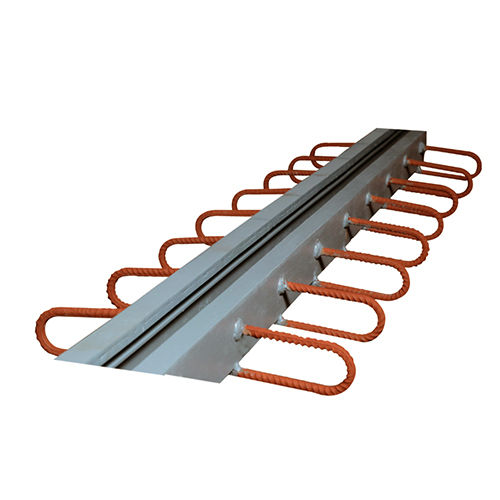

SCON STRIPSEAL F type expansion joint is suitable to accommodate 80 mm movement as per IRC SP 69.

Our F section is single monolithic section and is heaviest in weight and no welding or joint in our section.

We supply joints with studs as well as loop type anchors.

We supply MODULAR as well as Figure type joints as per structural requirement.

We provide warranty on all our products as per MORTH guidelines.

We provide warranty on all our products as per MORTH guidelines.

Advanced Movement AccommodationStripseal Expansion Joint enables structural movement up to 80 mm, vital for the longevity and safety of bridges, highways, and parking structures. The linear strip design ensures smooth movement without compromising stability or load-bearing capacity, maintaining seamless performance under thermal expansion and load variations.

Superior Material CompositionManufactured from galvanized steel and neoprene rubber, this joint excels in durability and weather resistance. The steel is compliant with ASTM A36/EN10025, while the 70 5 Shore A rubber seal offers high resilience. Its surface receives an additional corrosion-resistant treatment to ensure reliable life span, particularly in harsh environments.

Efficient Installation and CompliancePre-assembled and featuring bolt-on installation, the Stripseal Expansion Joint dramatically reduces on-site labor requirements. It adheres to vital standards such as IRC:SP:69 and BS EN 1337-8, guaranteeing safety, quality, and compatibility in both new and retrofit infrastructure projects.

FAQs of Stripseal Expansion Joint:

Q: How is the Stripseal Expansion Joint installed on bridge decks or highways?

A: The Stripseal Expansion Joint is supplied pre-assembled for quick and efficient fixation. Installation is performed using a bolt-on technique, allowing secure attachment and minimizing on-site construction time across bridge decks, highways, and similar structures.

Q: What materials are used in the construction of the Stripseal Expansion Joint?

A: This expansion joint comprises galvanized steel, conforming to ASTM A36/EN10025, and neoprene rubber with a hardness of 70 5 Shore A. The joint is hot rolled, precisely extruded, and treated with a corrosion-resistant coating for enhanced durability.

Q: When should a Stripseal Expansion Joint be used in construction projects?

A: Stripseal Expansion Joints are ideal for situations requiring movement accommodation up to 80 mm, especially in locations subjected to heavy vehicular load or thermal expansion, such as bridge decks, highways, and multi-level parking structures.

Q: Where is this product typically applied for best performance?

A: Optimal applications include bridge decks, highways, and parking structures. Its robust construction, weather resistance, and load-bearing capabilities make it suitable for areas with heavy traffic and environmental exposure.

Q: What process ensures the joints reliability and compliance with standards?

A: The joints reliability stems from precision extrusion, hot rolling, and surface treatment techniques, following strict compliance with IRC:SP:69 and BS EN 1337-8 standards, ensuring safety, strength, and long-term performance.

Q: How does the Stripseal Expansion Joint benefit infrastructure projects?

A: It provides reliable movement accommodation, high load-bearing capacity, and weather resistance. These features help prevent structural damage caused by expansion, contraction, or heavy traffic, supporting longer service life and reduced maintenance needs.