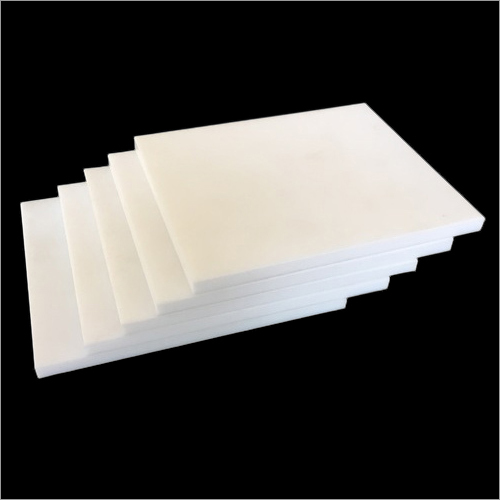

About PTFE Bearing Pad

Our offered PTFE Bridge Bearing Pad is used to accommodate construction irregularities like rotation and non-parallel load bearing surfaces. It is widely used in fast growing infrastructural projects like metro, railway bridges and flyovers. Our offered bearing pad is made under the guidance of our expert professional by using latest technologies keeping in mind the set industrial norms. This bearing pad is checked by our quality controller on different quality parameters before delivering to our valued customer end. Further, our provided PTFE Bridge Bearing Pad provides a covering for other products and water resistant.

Product Details

| Application | Bridge Construction |

| Material | PTFE |

| Thickness | 10-100 mm |

| Temperature Range | - 45 Deg C to + 120 Deg C |

| Hardness | 40 Shore A Approx |

Engineered for Reliable Structural SupportPTFE Bearing Pads are crafted for optimal load transfer and vibration dampening across diverse construction sectors. Their advanced design enables them to withstand high compressive forces while ensuring minimal friction, making them essential for dynamic environments such as bridges and industrial machinery bases. The strong PTFE-steel bond provides durability and longevity, even under severe temperature fluctuations and corrosive conditions.

Tailored to Your Project NeedsAvailable in various shapesrectangular, square, or circularand custom dimensions, these bearing pads can be manufactured to meet specific structural requirements. Their edge treatment options, such as chamfered or square, enhance fit, and installation convenience. The absence of a conventional retainer and the self-lubricating PTFE layer ensure smooth, maintenance-free operation, while the robust backing guarantees long-term structural integrity.

FAQs of PTFE Bearing Pad:

Q: How are PTFE Bearing Pads typically used in construction projects?

A: PTFE Bearing Pads are commonly used for structural load transfer and vibration isolation in bridges, buildings, and heavy machinery. They help accommodate movement due to thermal expansion, load shifts, and structural vibrations, reducing stress and ensuring stability in construction elements.

Q: What benefits does the highly polished PTFE surface provide?

A: The highly polished PTFE surface ensures an extremely low coefficient of friction (0.050.1 during dry sliding), which minimizes wear and allows for smooth movement between surfaces. This results in reduced maintenance needs and longer service life for both the bearing pad and the structures it supports.

Q: What is the typical process for installing these PTFE Bearing Pads?

A: Installation involves placing the bearing pad between two structural componentssuch as beams, girders, or machinery bases. The pads can be supplied with either chamfered or square edges for optimal fit, and custom sizes are available to match specific project requirements. No additional lubrication or special sealing is necessary due to their self-lubricating properties.

Q: Where are PTFE Bearing Pads most commonly applied?

A: These bearing pads are integral to bridges, buildings, heavy machinery, and various structural joints. Industries relying on large-scale load transfer and vibration damping, such as infrastructure development and industrial construction, frequently utilize them for their durability and versatility.

Q: What sets these PTFE Bearing Pads apart from conventional bearings?

A: Unlike conventional bearings, these pads employ a self-supporting, self-lubricating PTFE sliding layer bonded to a steel backing, providing excellent chemical and weather resistance. They do not require routine lubrication, have negligible water absorption, and can handle high compressive loads, making them highly suitable for demanding environments.

Q: Can the PTFE Bearing Pad dimensions be customized for specific projects?

A: Yes, both inner and outer diameters, as well as overall dimensions and thickness (typically 3 to 10 mm), can be customized according to project requirements. The pads are available in single row formats and various shapes to fit wide-ranging applications.