About RCC PT Slab

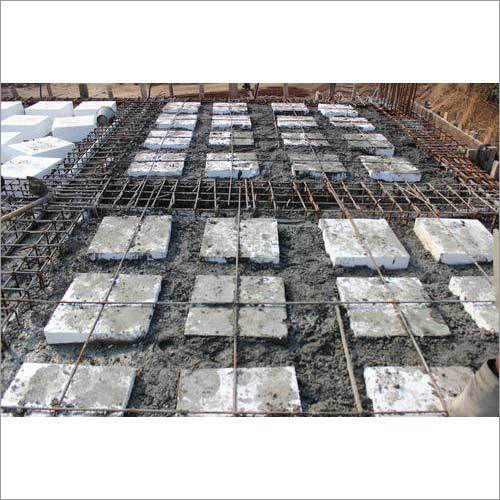

Our offered RCC PT Slab can reduce construction time, especially precast systems and place on flat-plate forming systems. Further, it can take advantage of post-tensioned reinforcement benefits to provide a thin slab with greater span. These voided slabs have been used in waffle slabs, single and double direction pan forming systems and hollow-core precast slabs. Apart from this, our provided RCC PT Slab can reduce construction time, especially precast systems and those placed on flat-plate forming systems.

Product Details

| Thickness | 350 - 400 mm |

| Usage/Application | Industral |

| Automation Grade | Manual |

| Material | Concrete |

Optimized for Versatility and PerformanceRCC PT slabs are engineered to support substantial loads and long spans, making them suitable for a wide spectrum of structuresfrom high-rise commercial complexes and residential apartments to industrial floors. Integrating high-strength, corrosion-resistant steel tendons, these slabs assure both structural integrity and longevity, meeting the unique needs of every project.

Adherence to Stringent Industry StandardsEvery slab is meticulously designed and crafted following IS 456 and IS 1343 guidelines. This commitment ensures structural safety, reliable performance, and peace of mind for architects, contractors, and owners alike. The cast-in-situ technique allows for customization tailored to client requirements, including waterproofing upon request.

FAQs of RCC PT Slab:

Q: How is an RCC PT slab installed?

A: RCC PT slabs are installed by casting them in situ (on site) and using on-site tensioning methods for the steel tendons or cables. This process ensures the slabs post-tensioned features are activated to handle the required loads and spans.

Q: What benefits does a post-tensioned slab offer compared to conventional slabs?

A: Post-tensioned slabs provide improved load-bearing capacity, can span longer distances (up to 15 meters or as required), and use materials more efficiently. They also demonstrate excellent crack control, high durability, and fire resistance.

Q: Where can RCC PT slabs be used effectively?

A: These slabs are ideal for commercial buildings, residential complexes, and industrial floors owing to their adaptability, span capability, and ability to meet specific load and design criteria. Their construction flexibility makes them suitable for various project requirements.

Q: What is the typical process for constructing an RCC PT slab?

A: The process involves setting up formwork, placing steel tendons or cables, pouring high-strength concrete (3050 MPa), and then tensioning the tendons after the concrete achieves sufficient strength. The surface is usually trowel-finished for an even, smooth look.

Q: How do you ensure the durability and resistance of PT slabs?

A: Durability is enhanced by using corrosion-resistant steel tendons and high-quality concrete. The slabs are inherently fire-resistant due to the RCC composition, and optional waterproofing can be added based on site requirements.

Q: What finishing options are available for RCC PT slabs?

A: Standard finishing is a trowel-smooth, cast finish ready for direct use or for covering with various flooring materials, making these slabs adaptable to different aesthetic and functional needs.