Call Us

07971258395

Call Us

07971258395

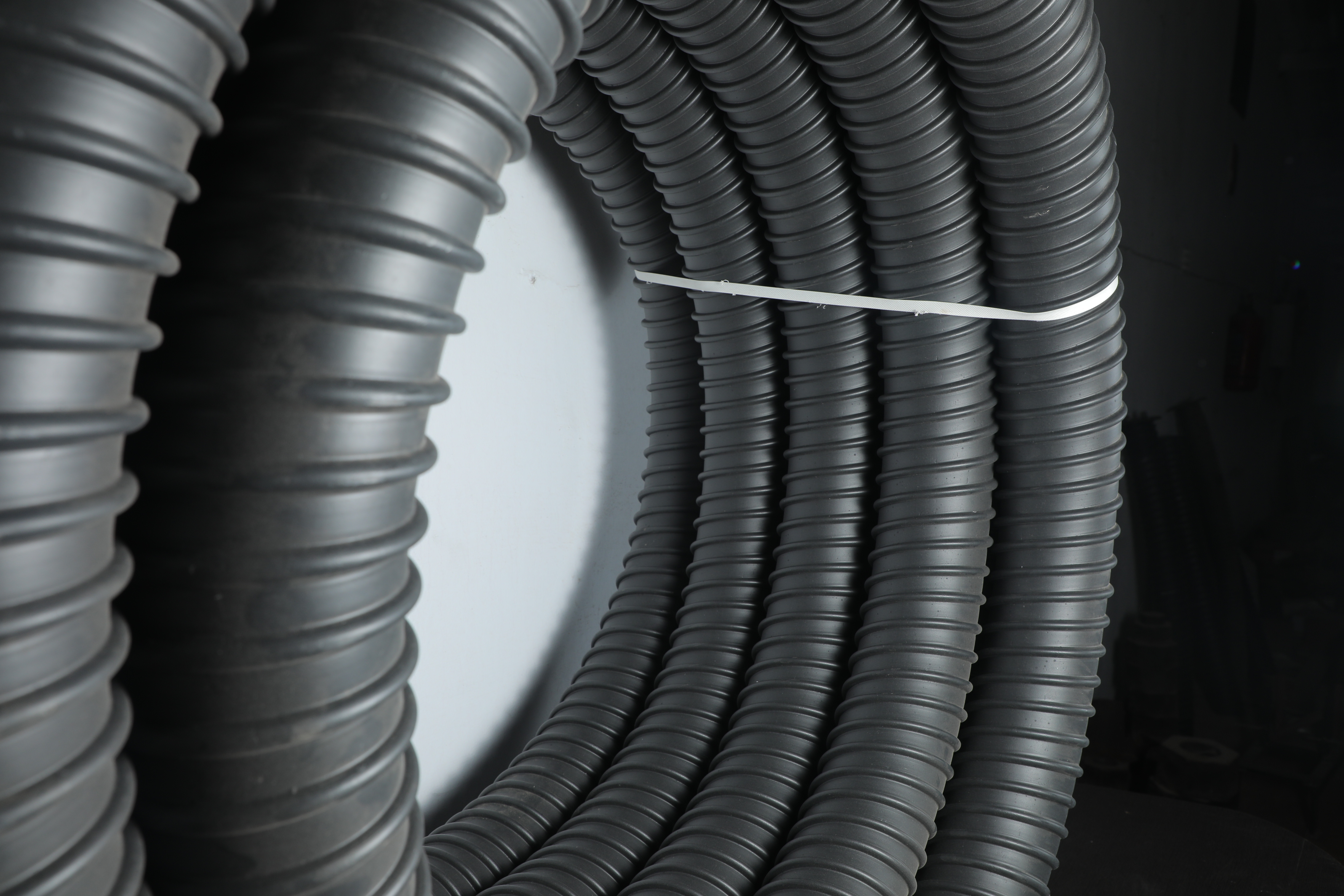

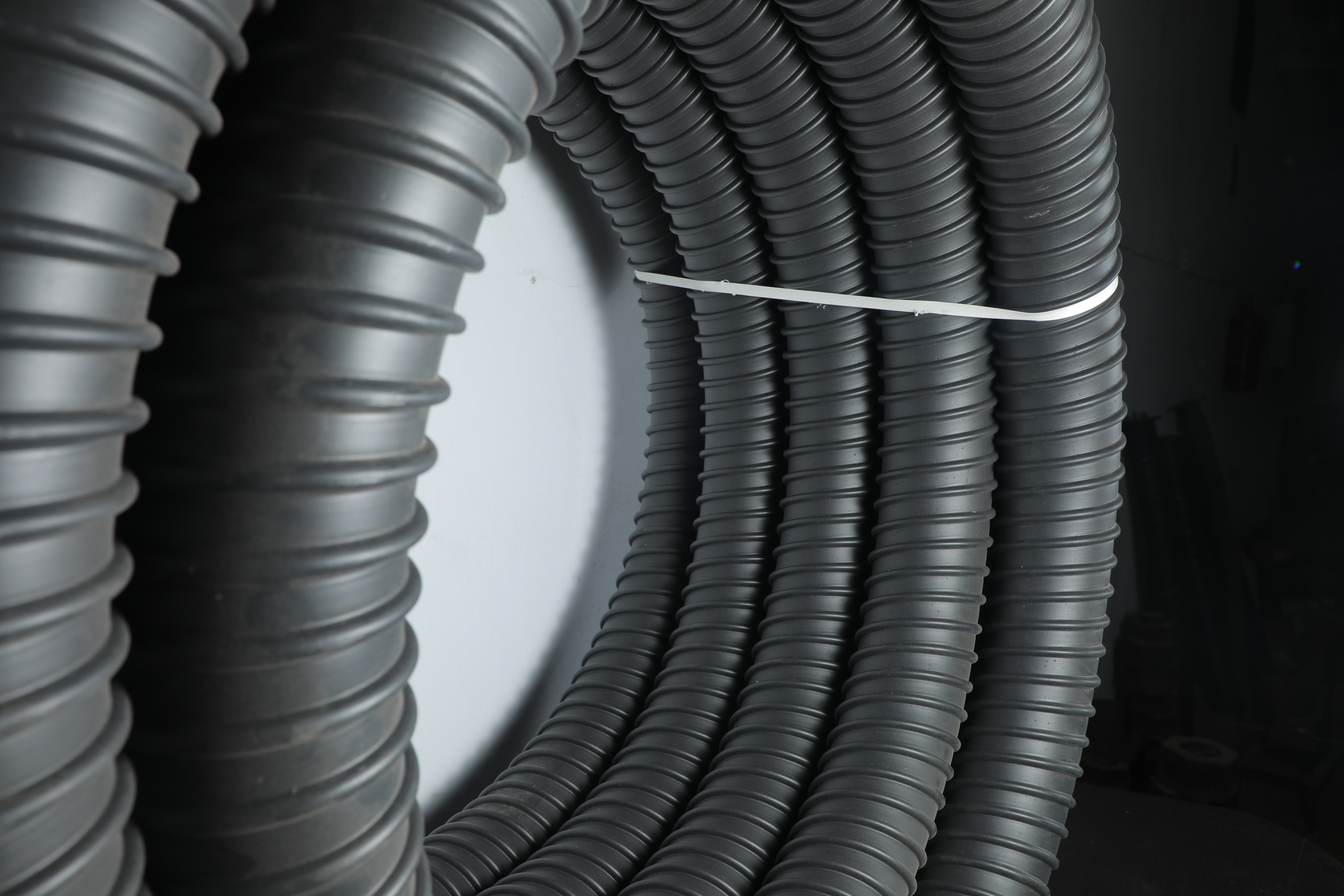

Our offered HDPE Circular Corrugated Pipe is resistant to corrosion and chemical attack, which is allowed to be used as holding vessel for floats in various applications. This corrugated pipe is made under the direction of our expert professionals by using high density polyethylene materials and sophisticated technologies as per the set industrial norms. Further, it is checked by our quality controller on different quality parameters before delivering to our valued customer end. Our provided HDPE Circular Corrugated Pipe is known for their unique features like free from infiltration and exfiltration, excellent resistance to corrosion and chemical attacks.

Product Details

|

IRC 18/ FIB |

For Bridges |

|

Unit Length |

6m |

|

Shape |

Round |

|

Thickness |

Up to 20 mm |

|

Flow Rate |

2 (Litre Per Hour) |

|

Size |

1.5,1.5" |

|

Material |

HDPE |

Price:

Price 50 INR / Meter

Minimum Order Quantity : 1000 Meters

Material : Other, HighDensity Polyethylene (HDPE) or Steel

Application : Other, Underground Drainage, Culverts, Sewerage, Stormwater Systems, Cable Protection

Connection : Other, Socket or Coupling

Technique : Other, Corrugated Forming, Spiral Wound or Continuous Pipe Forming

Price 200 INR / Meter

Minimum Order Quantity : 1000 Meters

Material : Other, High Quality Steel / Mild Steel

Application : Other, Post Tensioning, Prestressed Concrete Structures, Bridges, Flyovers

Connection : Other, Sleeve / Coupler

Technique : Other, Cold Rolled / Formed

Price 50 INR / Meter

Minimum Order Quantity : 20

Material : SS

Application : Industrial