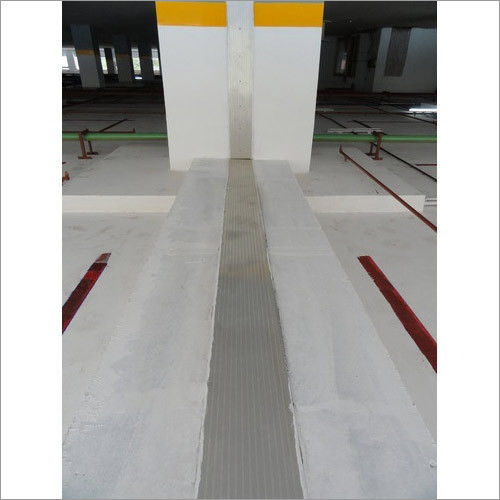

About Axial Wall Expansion Joint

Our offered Wall To Wall Expansion Joint facilitate variation in length without constraints and cracking, protect the surfaces of adjacent structural element and if necessary prevent the ingress of water. Our expansion joints are made under the guidance of dexterous professionals by using sophisticated technologies as per the set industrial norms. Our provided expansion joint is examined on predefined quality parameters to assure their durability and quality before delivering to our valued customer end. Further, this Wall To Wall Expansion Joint is available in different specifications and can be customized as per the needs of our valued customers.

Product Details

|

Available Diameter

|

20 mm, 23 mm, 25 mm etc

|

|

Usage/Application

|

Hydraulic Pipe

|

|

Size

|

1/2 inch

|

|

Material

|

Mild Steel

|

|

Feature

|

Easy Assembled

|

|

Expansion Joint Type

|

Wall To Wall

|

Versatile Connection SolutionsThis expansion joint features multiple end connection options, including flanged, welded, or threaded, to seamlessly integrate with a wide range of piping systems. The flanges can be drilled according to DIN, ANSI, or BS standards, providing flexibility and compatibility for installation in various industries.

High Performance and DurabilityDesigned to endure challenging operating conditions, the axial wall expansion joint is constructed with welded, anti-corrosive coated stainless steel bellows and a circular head code. This robust assembly allows for a working pressure up to 25 bar and ensures a typical service life of 20,000 cycles, making it a reliable long-term investment for pipeline systems.

Customizable for Unique RequirementsWith a wide size range (DN 50 to DN 2000), customizable finishes, optional internal sleeves, and accessories like tie rods and liners, this expansion joint can be tailored to meet specific application needs. Whether handling air, water, gas, or chemicals, its design supports both uni-directional and bi-directional flow and offers insulation provision for heightened versatility.

FAQs of Axial Wall Expansion Joint:

Q: How does an axial wall expansion joint help manage pipeline thermal expansion and vibration?

A: The axial wall expansion joint absorbs movements caused by thermal expansion, contraction, and vibrations in pipelines, preventing stress and potential damage to the system. Its flexible stainless steel bellows allow the pipe to move axially while maintaining a secure, leak-proof connection.

Q: What is the recommended process for installing the axial wall expansion joint?

A: Installation should follow the manufacturers guidelines, ensuring appropriate alignment and connection type (flanged, welded, or threaded). It is crucial to inspect the joint for damage, select the correct size, and use compatible flange drilling standards such as DIN, ANSI, or BS for secure fitting. Internal sleeves or insulation, if required, should be positioned before final assembly.

Q: When should optional accessories like tie rods or liners be used?

A: Tie rods are recommended when you need to control the expansion joints range of movement or prevent overextension, while liners are beneficial in cases involving abrasive media or high-velocity flow. Both accessories provide additional protection to the bellows and extend the joints operational lifespan.

Q: Where can this expansion joint be utilized effectively?

A: This product is ideal for industrial pipeline systems handling air, water, gas, or chemicals, especially where vibration isolation and thermal movement absorption are critical. It suits refineries, chemical plants, power stations, and water treatment facilities, thanks to its wide size range, robust material, and customizable options.

Q: What are the main benefits of using stainless steel in this expansion joint?

A: Stainless steel offers high corrosion resistance, mechanical strength, and durability at elevated temperatures (up to 550C). Its polished or anti-corrosive coated finish further enhances resistance to harsh chemicals and weather conditions, ensuring longevity and reduced maintenance costs.

Q: How is leak-tightness verified during manufacturing?

A: Each expansion joint undergoes rigorous hydrotesting up to 1.5 times its working pressure to verify integrity and leak-tightness. This ensures safe operation under demanding pipeline conditions and compliance with safety and quality standards.