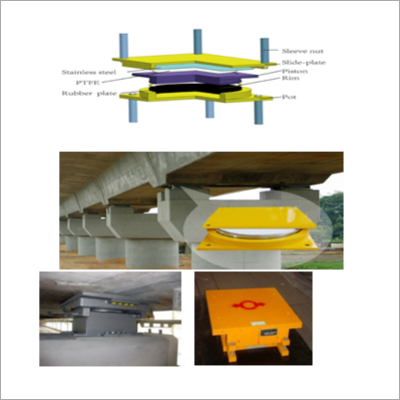

About Bearings .

Damping rubber made bridge Bearings have been developed as per EN 15129 standards. Usually, damping co-efficiency of such products ranges between 15% to 30%. Approved by SIO, these are used for protecting bridge structure against earthquake. Operating temperature of these bridge Bearings ranges between -45degree C to 60 degree C. Advanced design of these products extends longevity of concrete structures by improving their stress bearing capacity. Due to their better horizontal force and horizontal displacement enduring performance, these play significant role in avoiding seismic effect.

Precision and DurabilityManufactured with a hardness of HRC 60-64, our bearings deliver enduring performance in demanding environments. The chrome steel construction and steel retainer enhance their resistance to wear, corrosion, and deformation under stress, ensuring longevity and consistent reliability for a wide range of industrial uses.

Versatile Application RangeDesigned for usability in industrial machinery, automotive systems, and electric motors, these ball bearings provide low-noise operation and high dynamic load ratings. Their compatibility with both grease and oil lubrication allows flexibility based on specific requirements, making them suitable for various maintenance regimes.

Global Supply and SupportAs an established exporter, importer, manufacturer, service provider, supplier, and trader based in India, we cater to worldwide markets. Our proven expertise guarantees dependable bearings, comprehensive technical support, and tailored solutions for your operational needs.

FAQs of Bearings .:

Q: How do I determine the appropriate bearing seal type for my application?

A: Choosing between open and sealed bearing types depends on your environment and maintenance strategy. Open bearings are ideal for clean settings where regular lubrication is accessible, while sealed bearings provide enhanced protection against dust and moisture, suitable for harsher industrial conditions.

Q: What benefits do these bearings offer for high-speed motor applications?

A: These deep groove ball bearings support high limiting speedsup to 15,000 RPM with grease and 18,000 RPM with oilensuring smooth and low-noise operation. Their robust structure and precision rating help maximize motor efficiency and lifespan.

Q: Where can these bearings be utilized in the automotive industry?

A: Their high load capacity, corrosion resistance, and ability to withstand wide temperature ranges (-30C to 120C) make them suitable for automotive systems including transmissions, wheel hubs, alternators, and electric propulsion components.

Q: What is the manufacturing process for these chrome steel bearings?

A: Our bearings are produced using advanced forging, precision machining, and polishing techniques. Each bearing undergoes strict hardness and finish tests to ensure compliance with specifications and optimal durability.

Q: When is it necessary to use bearings with higher precision ratings (P6, P5, P4)?

A: Bearings with higher precision ratings are recommended for applications demanding superior accuracy and reduced play, such as high-speed industrial machinery, robotics, or critical automotive components.

Q: How does corrosion resistance benefit the bearings operational life?

A: Corrosion-resistant materials and polished finishes safeguard the bearings from moisture, chemicals, and debris, reducing maintenance needs and extending service life in challenging environments.

Q: What lubrication types are compatible with these bearings and why?

A: These bearings are compatible with both grease and oil, allowing users to choose based on speed and operating temperature requirements. Grease offers longer intervals between maintenance, while oil enables higher RPM and efficient heat dissipation.