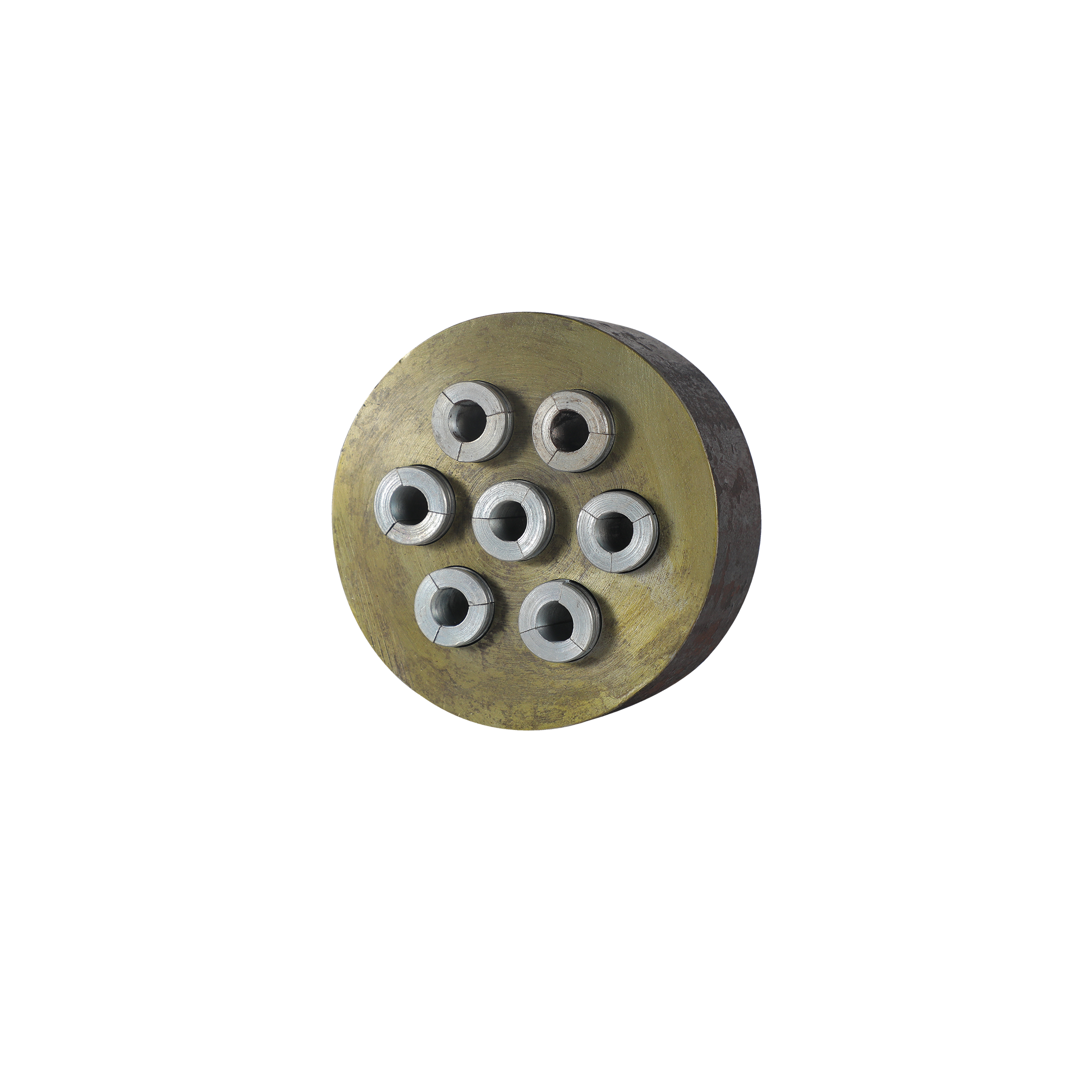

About Anchor Head

Anchor Head

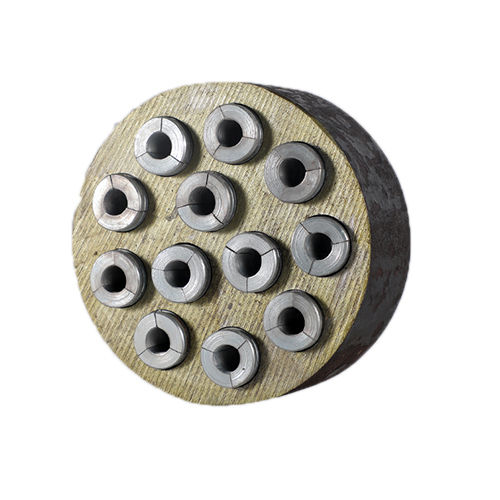

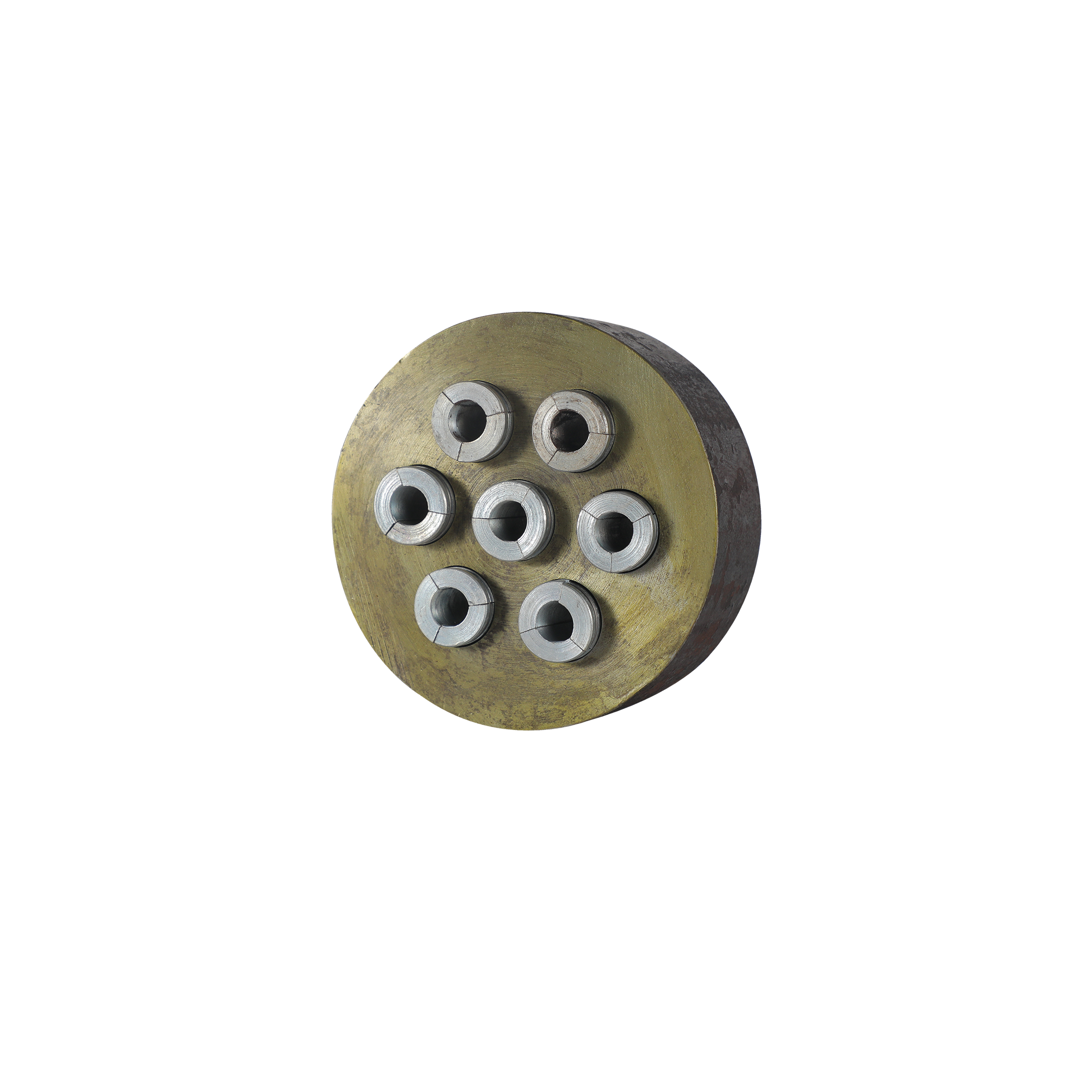

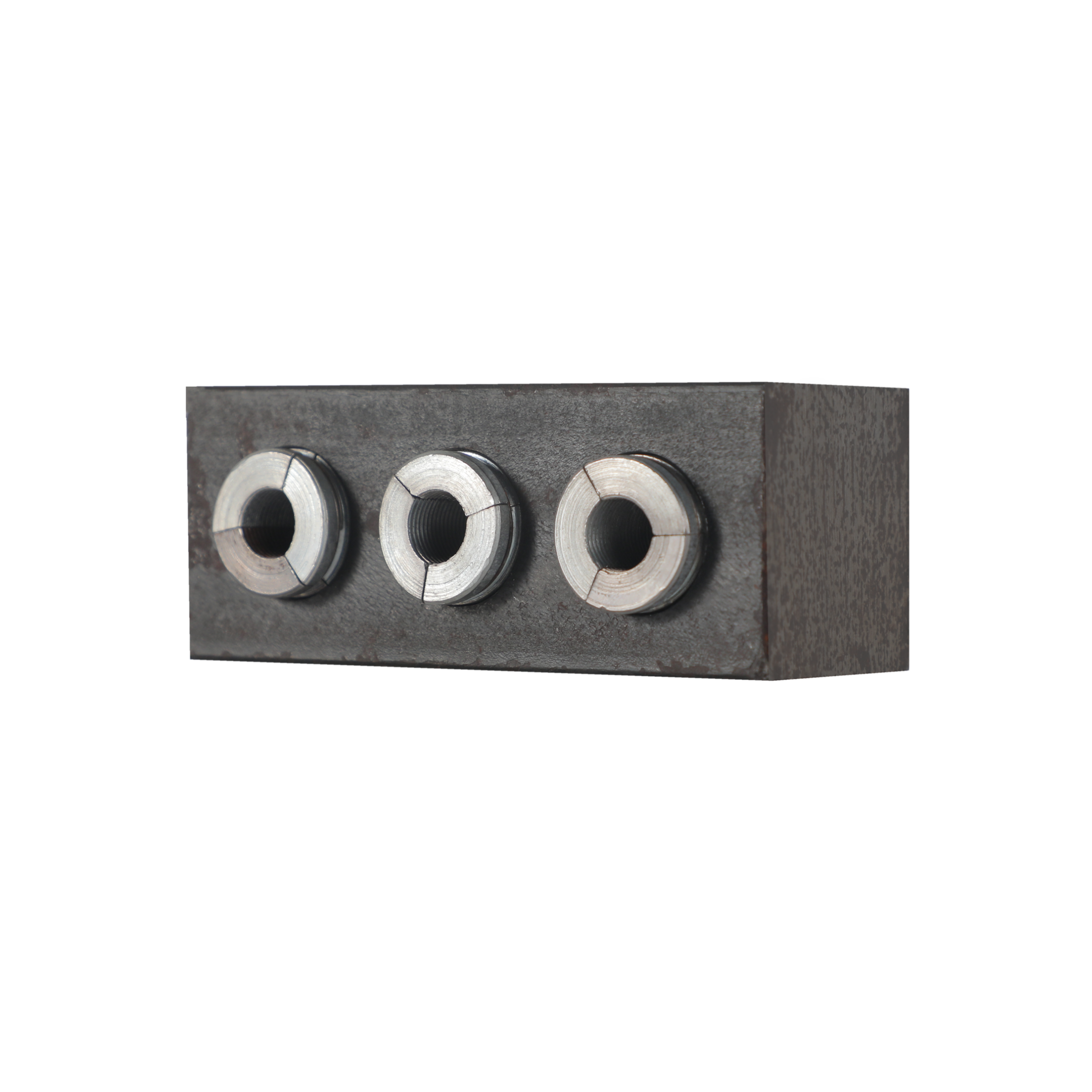

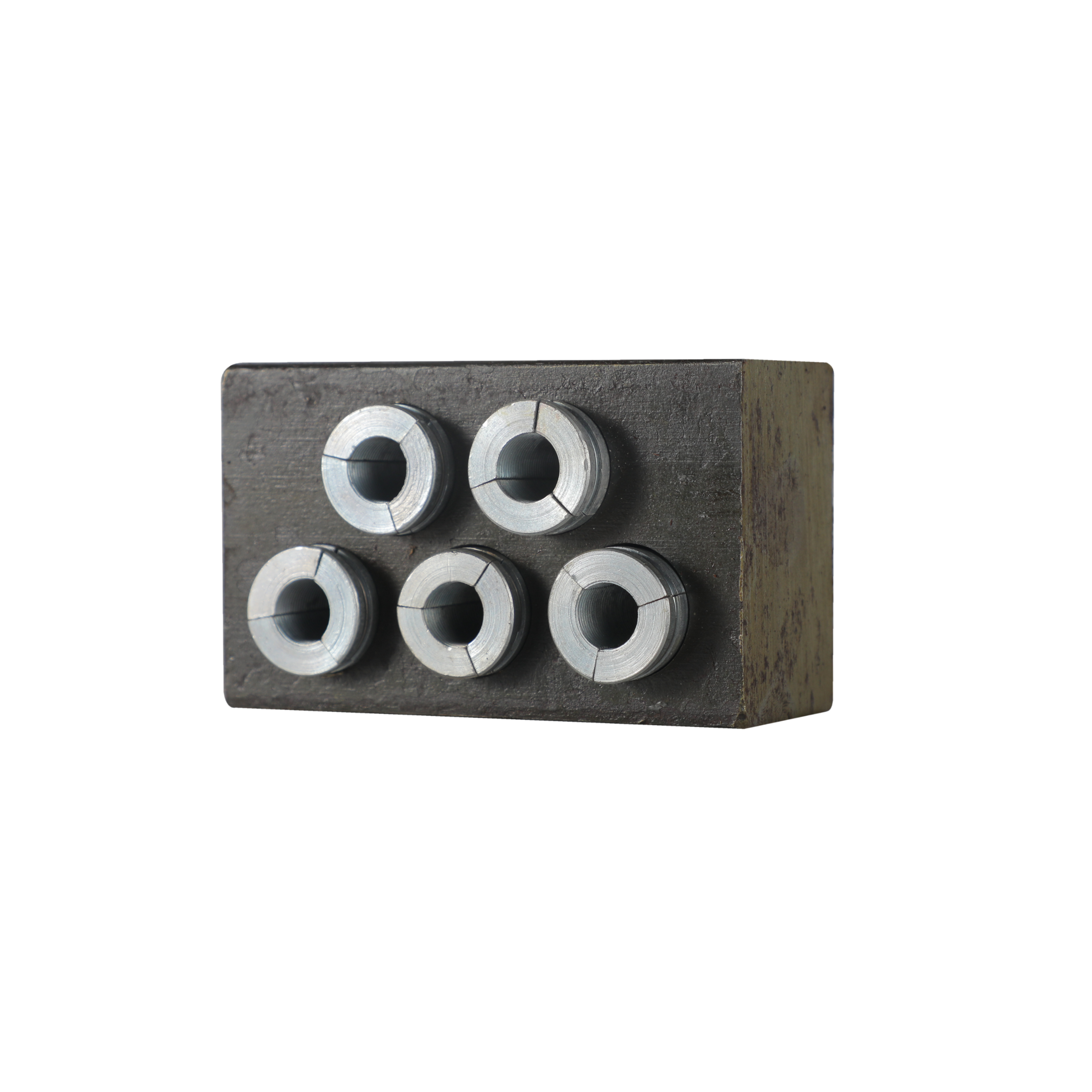

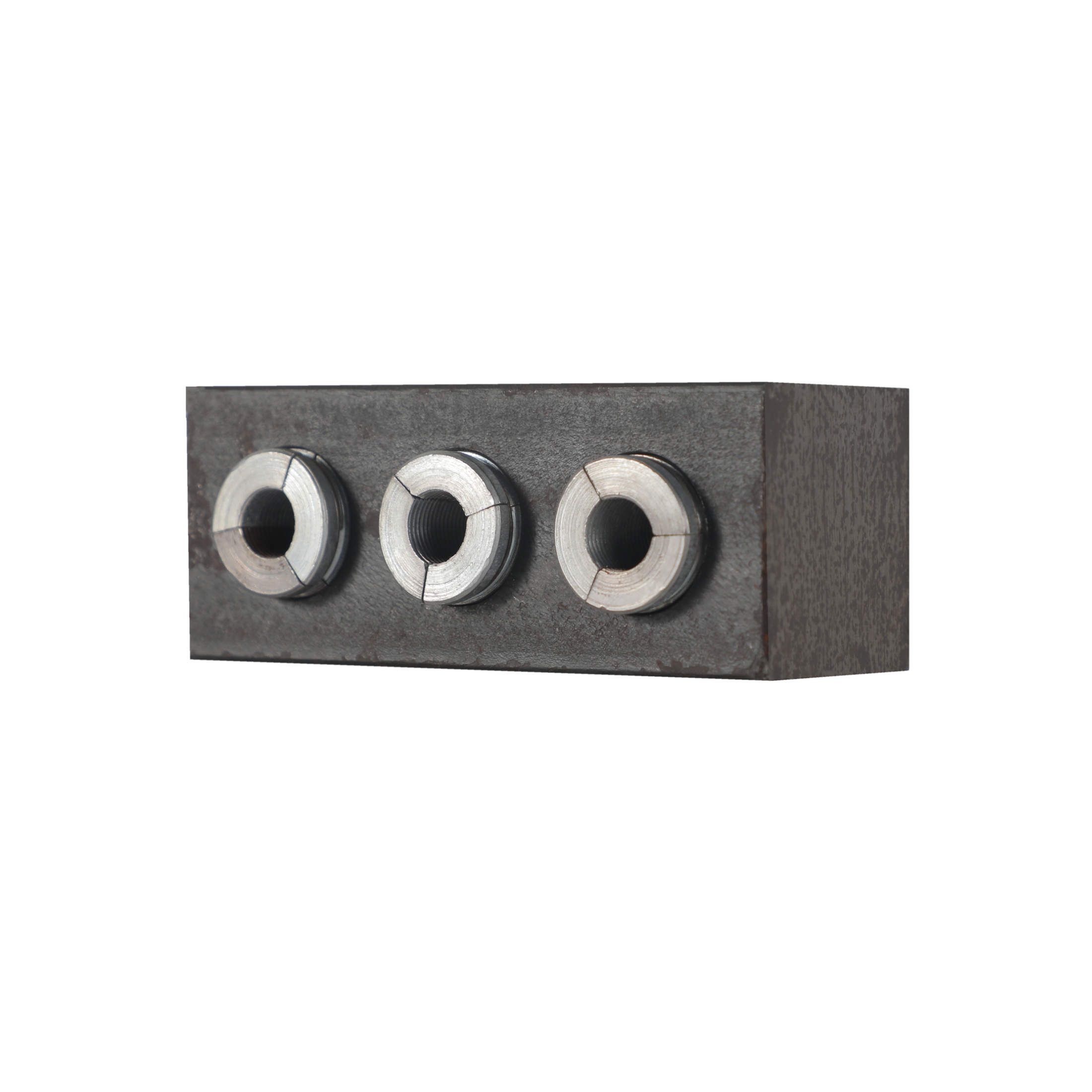

We are dealing in the manufacturing and supplying of highly rigid Anchor Head which is manufactured by using heavy engineering materials which imparts greater strength and rigidity. This metallic component is commonly used in post tensioning in heavy civil structures which includes bridges, building floor slabs, water tank, silos railway and bridge girders. It is machined with high precision by using latest machining technologies which gives higher dimensional accuracy and makes it free from manufacturing flaws.

Durable Construction for High-Pressure ProjectsEngineered to endure rigorous conditions, the AH-12 Anchor Head excels in settings where high working pressures and temperatures are essential. Its galvanized finish ensures additional longevity, making it well-suited for post-tensioning applications in bridges, buildings, and large infrastructure projects.

Expert Forging TechniqueEach AH-12 Anchor Head is manufactured using advanced forging processes, ensuring uniform strength, precise dimensions, and resilience under challenging environments. The forging, combined with a galvanized treatment, provides superior mechanical properties and protection against rust or corrosion.

FAQs of Anchor Head:

Q: How is the AH-12 Anchor Head installed in post-tensioning systems?

A: The AH-12 Anchor Head is typically placed at the end of tensioned tendons in a post-tensioning system. It is fixed using specialized post-tensioning equipment, ensuring a secure and stable hold within structural concrete applications.

Q: What are the main benefits of using a forged and galvanized anchor head?

A: Forging imparts greater strength and consistency to the anchor head material, while galvanization adds a protective layer against corrosion. This combination leads to increased durability, reliability, and a longer service lifespan, even in harsh environments.

Q: Where can the AH-12 Anchor Head be utilized effectively?

A: The AH-12 Anchor Head is ideal for use in civil engineering works, such as highway bridges, commercial and residential buildings, parking structures, and other infrastructure projects that require robust post-tensioning components.

Q: What is the maximum working pressure and temperature that the AH-12 Anchor Head can handle?

A: The AH-12 Anchor Head is rated for a working pressure of up to 45 MPa and can operate in environments with temperatures as high as 300C, making it suitable for heavy-duty structural applications.

Q: What is the process used to manufacture the AH-12 Anchor Head?

A: This anchor head is produced using a forging process, which shapes the metal under high pressure to achieve required strength and dimensional accuracy. The product then undergoes galvanization for enhanced surface protection.

Q: Who supplies, exports, and manufactures the AH-12 Anchor Head in India?

A: The AH-12 Anchor Head is available through established exporters, importers, manufacturers, suppliers, traders, and service providers across India, recognized for quality and timely delivery in the construction industry.